Case Study: 6298 What separates a good automation system from a great one? True partnership and a commitment to continuous improvement.

A leader in the electric motor manufacturing industry approached us to build upon a previous success. Their first-generation automated machine proved the concept, but a second-generation system was needed to handle a wider variety of parts, increase throughput, and improve long-term reliability based on real-world production feedback.

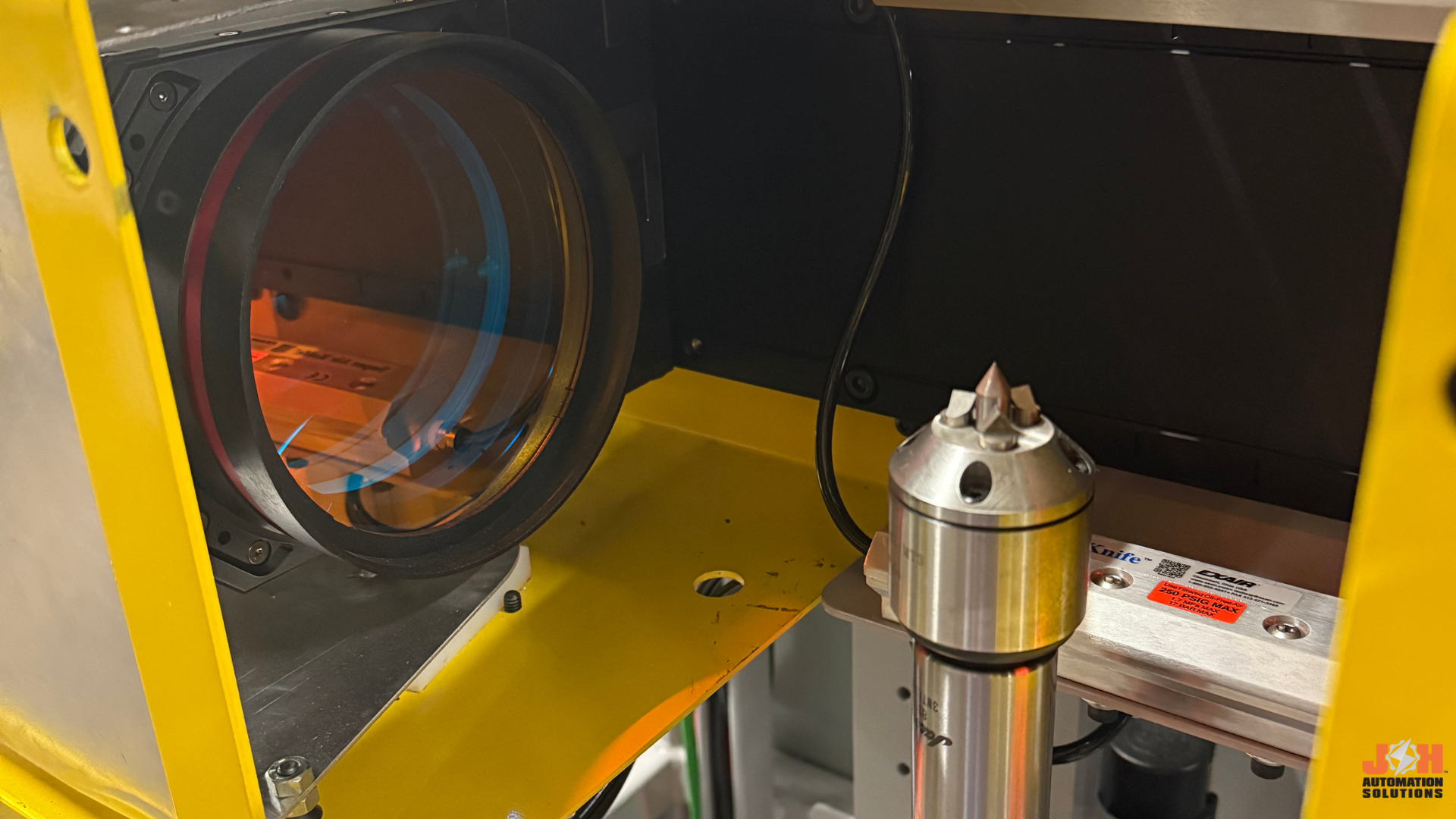

Leveraging insights from the original machine, the J+H Automation team engineered a completely redesigned and more robust solution. The new system uses a high-precision Keyence telecentric measuring system to perform complex, non-contact measurements as the part is automatically rotated. To address the demanding environment, we implemented key mechanical upgrades, including a heavier-duty gearbox and a redesigned servo motor mount. The entire process is driven by a powerful and precise motion control system, orchestrated by an Allen-Bradley CompactLogix PLC and Kinetix servo drives for ultimate reliability.

The result is a next-generation custom machine that is more capable, more durable, and perfectly tailored to the client's evolving quality control needs. This project showcases our commitment to not just delivering a machine, but to building a long-term partnership that refines and perfects automation solutions.

Beyond the initial installation, we build partnerships that last. If you're looking for an automation partner dedicated to evolving with your needs, let's talk about your next project.